Paper and recycling have been going together for more than a thousand years. After it was discovered in Japan in the ninth century that paper could be reused, the recycling of paper not only acquired economic value, but also sentimental value. For example, in the 12th century, an emperor’s widow, after his death, recycled all the poems and letters she had received from him. She then wrote a poem on the recycled paper to commemorate him (source).

We have never stopped recycling paper. Today, paper has a global recovery rate of 58.6% and we do even better in Europe. Here, no less than 72.5% of paper is reused and only 27.5% is lost (source). But why have we been recycling paper for so long and so willingly? And after all these centuries of paper production, is recycling still the best environmental solution for producing paper?

WHAT IS RECYCLED PAPER?

Paper recycling is a process whereby new paper products are made from waste paper. There are different categories of recovered paper that are suitable to be used as raw material for recycled paper:

– Factory waste: paper shreds and other paper waste left over from paper production and then recycled in the same paper factory. Paper is therefore never lost.

– Pre-consumer waste paper:: paper products that have left the paper factory but have never reached the consumer. It has therefore already become waste paper before it has been used. For example, paper at printing works which remains as cutting waste during production. Or paper that cannot be used by printers because of its specifications (size, grammage). Pre-consumer paper made from trees is therefore unused and unprinted paper, without ink. It does not cause any pollution in the recycling process. This is the highest quality recycled paper.

– Post-consumer waste paper:paper that is thrown away by consumers and companies after use, such as packaging material made of paper and cardboard, old newspapers, magazines, printing paper, envelopes, drinks cartons. These types of paper therefore always have contamination in the form of ink, staples, paper clips, glue, window foil, polystyrene foam, food residues, dust and sand that do not belong in wastepaper.

EN 643: EUROPEAN STANDARD FOR DIFFERENT TYPES OF PAPER FOR RECYCLING

The European Union has made a list of up to 50 different types of recycled paper. This list is laid down in the standard EN 643 different paper types for recycling. After paper has been processed into packaging or printed matter, it can be recycled. Just as a baker can bake different types of bread (white bread, wheat, multigrain), paper mills can make different types of paper and cardboard (thick, thin, firm, flexible, strong, white, brown, etc.). There is a paper grade for every application. The quality of paper for a newspaper is completely different from the quality of corrugated cardboard boxes, which in turn is very different from drinks cartons or printing paper.

Paper consists of cellulose fibres in the base. This cellulose comes from different sources. Think of different types of trees (eucalyptus, birch, pine, etc.). But cellulose also comes from agricultural waste, stems and leaves that remain after harvesting wheat, barley, rice, sugar cane and other crops. All these cellulose fibres have different properties and characteristics. This makes it possible for the paper industry to produce different types of paper and cardboard from the different types of recycled paper. The EN 643 standard helps the paper recycling companies and the paper mills to sort the different kinds of recovered paper. Each grade has a different price and different characteristics. This EN 643 standard makes it possible to recycle more paper, improves the quality of the recycled paper and makes it possible to produce higher quality paper and cardboard packaging and printed matter.

WHY IS PAPER RECYCLED?

The production of new paper has a considerable negative impact on the environment. Ancient forests or agricultural land are rapidly being transformed into plantation forests for the production of paper. Plantation forests are a monoculture that do not contribute to biodiversity. These plantation forests are often FSC certified, which leads the market to believe that the paper is sustainable. In addition, the production of paper requires a lot of energy. Many may not (yet) be aware of it, but the emissions of the total paper industry are now greater than those of aviation (source)!

Therefore, the more paper we recycle, the smaller the impact on the environment will be. Paper has been recycled for over a thousand years. Initially, this was done mainly for economic reasons: all the energy, water, raw materials and labour already invested in new paper did not have to be invested again, which made recycling interesting. Nowadays, this is no longer the main motivation for recycling paper. Sustainability has become more and more important and recycling is a better option from an environmental point of view. Today, that is the main reason for the great interest in recycled paper.

But this means that you have to recycle paper. Because if paper is not recycled and ends up in the bin instead, it ends up where other waste ends up: in incinerators or on landfills. Everyone understands that what you burn is gone – gone potential raw material, gone opportunity for the best environmental benefit. As soon as paper ends up in landfills, the damage is even greater. Landfills, which many countries around the world still use, are considered a major source of methane emissions into the atmosphere. Methane is a greenhouse gas, just like CO2, but 25 times stronger and therefore more negative for global warming. Paper and cardboard is organic material, which causes a lot of methane gases to be released during decomposition (source). Both incineration and landfill are therefore not at all environmentally friendly.

HOW IS RECYCLED PAPER MADE?

Recycled paper is relatively easy to produce, with end products that can compete with new materials in terms of quality. The days when recycled paper was easy to recognise by its colour are now long gone. Even recycled paper can be as white as snow and is almost indistinguishable from new paper. A number of steps have to be taken to achieve recycled paper.

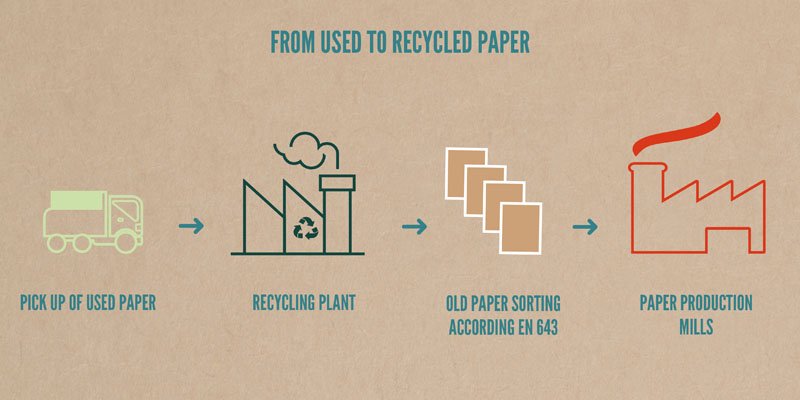

The used paper is collected from companies and consumers by waste processing companies and paper collection companies. This waste paper stream is taken to recycling companies where the paper sorting takes place. The paper and cardboard are separated and divided into different types and quality classes. This is done according to the EN 643 standard. The paper sorting companies then sell the waste paper to the paper factories. Not every paper factory can just recycle paper. After all, used paper must first be cleaned. All inks, staples, paper clips, glue residue, window film, plastic, sand and dust must be removed.

A paper mill must therefore be designed to be able to process waste paper into recycled paper. Cleaning old paper is a bit like a washing machine. The soiled waste paper is collected in a large container and mixed with water and a kind of soapy water. We call this process paper pulping. The paper pulp is then cleaned through all kinds of filters, sieves and separation techniques. In the end, a little over 99% of the water and 1% of cellulose fibres remain. These cellulose fibres are sprayed onto the sieve of the paper machine in the paper factory. The thicker the layer of paper on the screen, the heavier the grammage per square metre.

By adding various substances to the paper pulp and by choosing a mix of recovered paper types, different paper products can be made such as tissue paper, printing paper, newsprint, wet strength paper, folding carton, corrugated board. Paper machines have different dimensions. The largest are longer than 400 metres and can produce rolls of paper up to 11 metres wide. The rolls of paper coming from these machines weigh up to 70 tonnes. Paper is then cut into the required roll widths and large format sheets to be delivered to wholesalers, printers and cardboard companies.

HOW OFTEN CAN PAPER BE RECYCLED?

It is a misconception that paper and cardboard can be recycled infinitely. Most articles on “paper recycling” give the number 7 as the number of times paper can be recycled. Once waste paper arrives at the paper recycling plant it must first be wetted and softened. This happens in the pulper, a large steel container with a rotor in the middle. For each production batch, several thousand kilos of waste paper of different qualities are put into the pulper. Water is added and then the rotor starts to turn. It is a large mixing machine. As the rotor turns, the paper rubs against the rotor and against each other, causing friction and heat. During this process, the cellulose fibres can come loose from the dirt, but the cellulose fibres also break.

Cellulose fibres that remain long enough are recycled into recycled paper and fibres that are too small and short are filtered out of the system together with ink residues. So every time waste paper is recycled, part of the waste paper is lost. This explains why the paper industry writes that waste paper can be recycled 7 times. This is a theoretical number. Actually, the words “paper recycling” are not quite right. We should actually call the process of paper recycling “paper downcycling”. The value of old paper as a raw material devalues each time it is recycled. And that explains why we cannot use only recycled paper. In the raw material chain of paper recycling there always has to be fresh long cellulose fibres.

IS RECYCLED PAPER FOOD GRADE?

No, in principle recycled paper is not food grade. Old paper contains dirt in the form of inks, staples, paper clips, glue residue, window film, plastics, food residue, sand, dust, etc. Because the paper mill is only interested in cellulose fibres (from which paper can be made again), the paper mill only removes all substances that are not cellulose fibres. This purification process works quite well, but not 100%. Ink residues in particular are very difficult to separate from the fibres. Inks are chemical raw materials that contain heavy metals and harmful chemicals. You can imagine that if the paper industry cannot guarantee a 100% phase-out of these substances, this recycled paper should not come into contact with food. All paper and cardboard packaging that comes into direct contact with food must either be made of 100% new, clean cellulose fibres, or there must be a protective layer between the food and the paper or cardboard. Think of a plastic or aluminium layer.

WISE WITH WASTE: YOU CAN BE EVEN MORE ENVIRONMENTALLY FRIENDLY WITH PAPERWISE PAPER

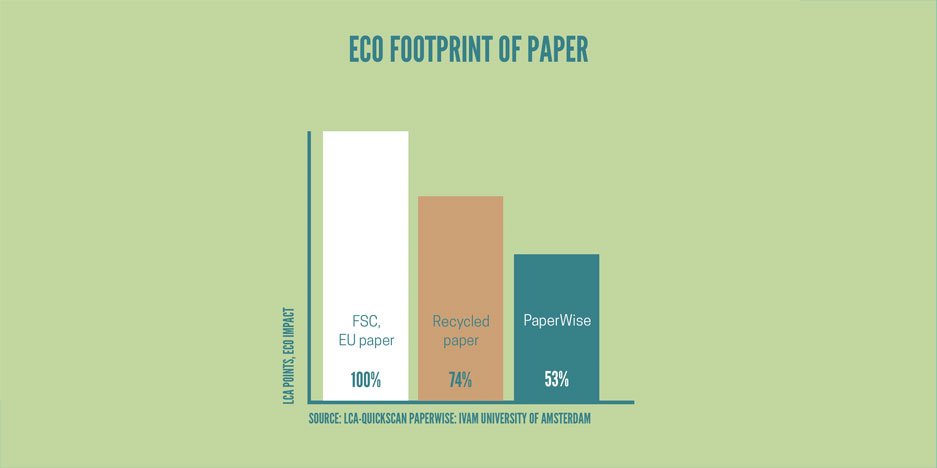

It is obvious that recycling paper is good for our planet. The environmental impact is smaller than paper made from trees and reusing raw materials is positive. But there is a method that is even more environmentally friendly: paper made from agricultural waste.

PaperWise’s vision is ‘Wise With Waste’. A lot of agricultural waste is burnt worldwide, while it could be processed into a perfect raw material for paper. PaperWise started to make paper and board out of this agricultural waste. The stems and leaves left on the land after the harvest are used to make high quality paper and board in an environmentally friendly way. This way, agricultural waste that would otherwise be burned is given a second life, and thus buyers of this paper reduce their ecological footprint in comparison to recycled paper or paper made from trees. Independent environmental research shows that the environmental impact of PaperWise is 29% lower than that of recycled paper and even 47% lower than that of paper made from trees (virgin paper).

Thanks to PaperWise paper, plantation forests for the paper industry become unnecessary. Trees no longer need to be cut down, but can be left to absorb CO2, which is converted back into oxygen. We can decide for ourselves what we want to do with these pieces of land! Use it for natural forests with a great diversity of life and biodiversity or use it for agricultural land. It is much smarter to get two products, food and the raw material for paper, from the same plant and the same piece of land.

CAN PAPERWISE PAPER ALSO BE RECYCLED?

Yes, PaperWise is excellent for recycling, up to seven times. And it can be mixed with the normal waste paper stream. PaperWise is not recycled paper, but new pure paper made of cellulose that is extracted from plant remains after harvest. PaperWise is therefore allowed to come into direct contact with food. This agricultural waste does not compete with human or animal food, it is really a waste from agriculture. About 20 percent of an agricultural crop is edible and is used as food. The other 80 per cent consists of non-edible leaves and stems and that is the waste from which cellulose for PaperWise paper is extracted.

By using agricultural waste as raw material, green energy where possible and CO2 compensation, PaperWise is CO2 neutral paper and board with a very low environmental impact. Without concessions to quality. PaperWise paper meets the highest quality standards and certifications and is suitable for virtually all printing applications. PaperWise guarantees a life of up to 100 years (suitable for archiving). However, a lot of paper will not need to be stored for that long and is eligible for recycling after a few years.

IS RECYCLED PAPER STILL THE MOST RESPONSIBLE?

In conclusion, with an environmental impact of PaperWise that is 29% lower than that of recycled paper and even 47% lower than that of paper made from trees (new paper), paper made from agricultural waste is even more environmentally friendly. We call that Wise With Waste.